As a company, Lesters thrives on innovation. We aim to create the perfect corrugated solution for our clients’ products that will not only increase efficiency and sustainability but, most importantly for your business, reduce costs. Today, we’d like to walk you through our guide to the Lesters design process.

Start

The first step of our design process is to open up communication with our new clients. We will invite you to our in-house design facility for an initial brief to build familiarity around your business.

Learn

Our passionate design team take a real interest in our customers. It’s important for us to understand your precise needs so we can create the perfect corrugated solution for your business.

Examine

Our experienced in-house design team undertakes an in-depth analysis of your current packaging process, studying the product, existing packaging, and how it is distributed.

Solution

The team begin to develop solutions, adjusting current FEFCO styles, or even creating bespoke designs from scratch. Sustainability is at the heart of our business so, where possible, we look to use solely corrugated materials, removing plastics and consumables.

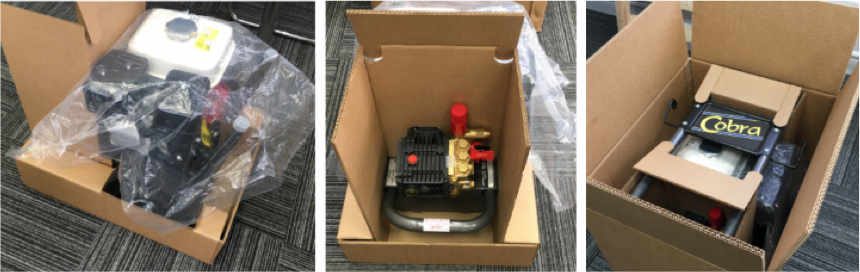

Test

Our design team put your pack through rigorous testing to ensure it can meet the demands of the supply chain. We can produce samples to test first-hand using our CAD software. This brings your product to life and offers an accurate representation of the final product.

Engage

We encourage your engagement and feedback at all stages of the development. At each stage, you will be sent updates, prototypes, and developments to ensure the final product is tailored to your exact needs.

Relationship

We have now created the perfect corrugated solution for your business and hope to build a long-term partnership with your company built on trust, fantastic service and a quality end product.